Expanding Your Manufacturing to Asia in 2026: A Practical Playbook for Brands Who Can’t Afford Guesswork

Why are brands expanding manufacturing to Asia in 2026?

2026 is not the year to “try Asia and see what happens.” It is the year to expand or rebalance manufacturing with a plan that protects cost, timelines, and compliance in parallel.

Most brands are not abandoning China; they are rebalancing production between China, Vietnam, India, Indonesia, and Bangladesh. China remains critical for components and know‑how, while Southeast and South Asia take on more final assembly and labor‑intensive products.

Three main forces are behind this:

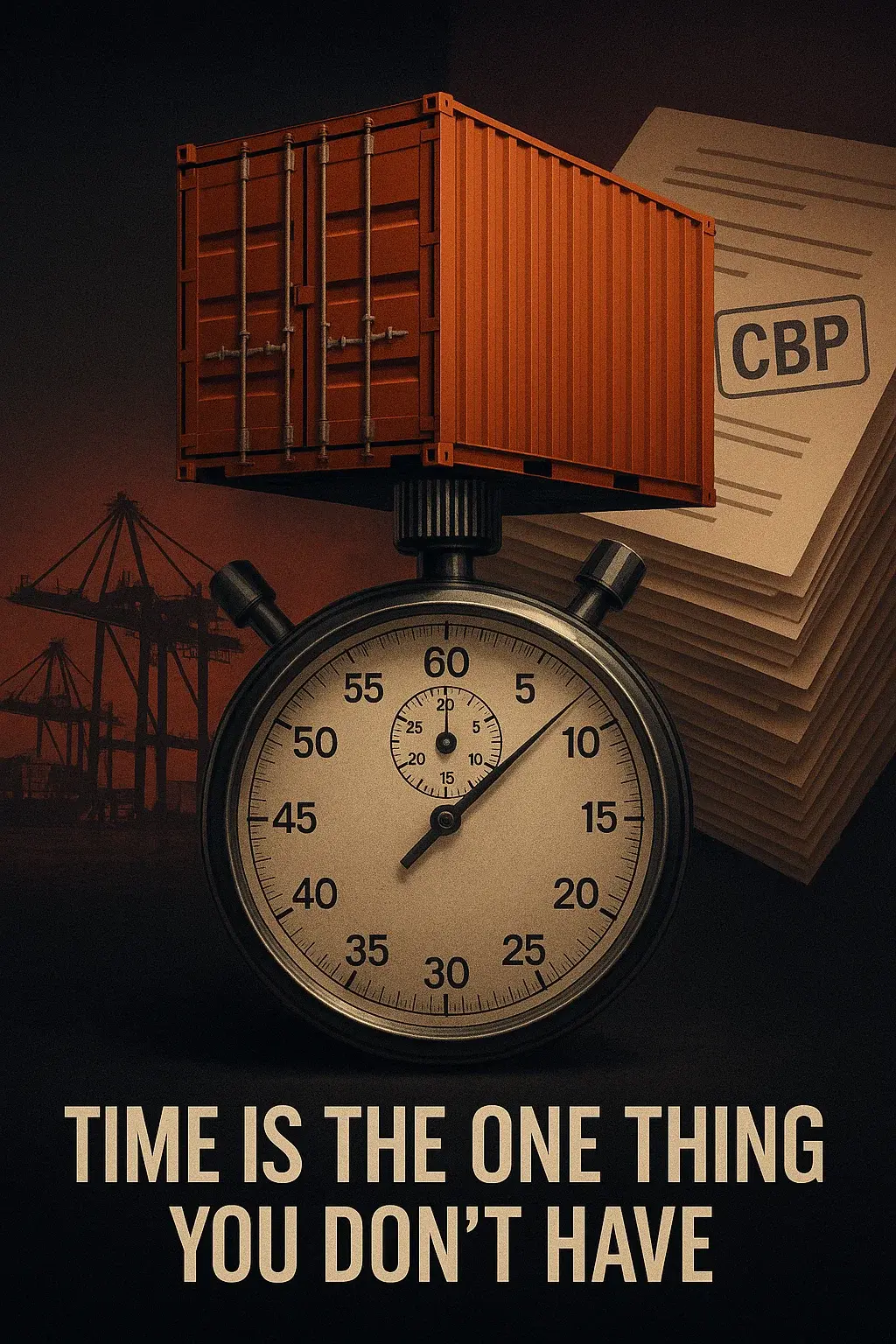

- Stricter enforcement on origin, UFLPA, and CBP “reasonable care” for imports from Asia.

- A need to reduce over‑reliance on one country without destroying margins.

- More available capacity in several Asian hubs, creating room for better pricing and MOQs if managed closely.

The opportunity is real, but moving production without moving control is where most problems start.

Which products should you move from China to Asia?

Not every product should leave China. Some SKUs perform best in China; others are ideal for Vietnam, India, Indonesia, or Bangladesh.

As a rule of thumb:

- Keep in China: Complex products, IP-heavy categories, and SKUs that depend on dense local ecosystems.

- Move to Vietnam or Indonesia: Labor‑intensive products, basic hard goods, simple assemblies, and tariff‑sensitive items.

- Move to India or Vietnam: Apparel, textiles, and categories where labor cost and scale matter most.

Before any move, map your BOM and supplier list. Without a clear map of materials, components, and factories, you cannot defend origin or explain your supply chain to customs later.

Key takeaway: Decide what to move and where using BOM and supplier data, not just gut feel.

How do you map your Asia supply chain properly?

Customs and regulators now look at the real flow of goods, not just what appears on invoices. If your documents and your actual supply chain tell different stories, CBP and other authorities will notice.

A simple supply chain map should answer:

- Where do raw materials and key components come from (China, Vietnam, India, etc.)?

- Where does substantial transformation happen (which factory, in which country)?

- Who owns and controls the critical factories and trading entities involved?

Document:

- A list of suppliers, their roles, and locations.

- A flow diagram from raw material to finished product.

Key takeaway: A clear supply chain map is your foundation for both diversification and CBP “reasonable care.”

How do you verify factories in Asia before placing POs?

Factory photos and WeChat messages are not verification. Proper supplier verification in Asia should cover identity, capability, behavior, and risk.

A practical “verify my supplier” process includes:

- Identity checks: Business license, registration, ownership, and related entities (especially in China).

- On-site visit: Real production lines, warehouse, and staff—not just a showroom.

- Capability review: Equipment, processes, sample room, and real WIP (work in progress) on the line.

- Risk assessment: Compliance history, export markets, basic documentation, and red flags (e.g., shell companies, mismatched records).

For higher-risk categories or countries, add:

- Background checks on owners and related companies.

- Deeper review of production, labor, and sourcing practices.

Verification is extremely hard to do well from another continent. Local teams in China, Vietnam, India, Indonesia, and Bangladesh can run these checks quickly and accurately.

Key takeaway: Never move production—or pay deposits—without a structured, on‑the‑ground verification of your factories.

How should you design quality control for Asia manufacturing?

Inspections at shipment are important, but they come too late to fix structural problems. Quality control for Asia manufacturing works best when designed into your process from the beginning.

A robust quality plan should:

- Translate every key spec into measurable checks at the factory.

- Define acceptance criteria before the first order, not after complaints start.

- Include in‑process checks at the most failure‑prone steps, not only final inspection.

- Build feedback loops: data from inspections and returns feeds into revised SOPs, packing, or processes.

Use pre‑production meetings and pilot runs to align expectations and test the plan under real conditions.

Key takeaway: Quality is set at onboarding and first production, not at the warehouse door in your home market.

What does CBP “reasonable care” mean for importers using Asian suppliers?

CBP does not expect perfection, but it does expect you to demonstrate that you exercised reasonable care. For importers sourcing from China, Vietnam, India, Indonesia, or Bangladesh, that means being able to show why you trust your data.

Practical “reasonable care” steps include:

- Documented supplier selection and verification (including factory visits when risk is high).

- Clear evidence of how you determined country of origin, classification, and valuation.

- Records of communications, contracts, test reports, and corrective actions.

Many importers build a digital “CBP readiness binder” per product line, containing:

- Supplier profiles and verification reports.

- Contracts and key legal documents.

- Test reports, audits, and inspection records.

Key takeaway: Reasonable care is a system, not a one‑off document—build it into your daily sourcing and QC routines.

Do you need your own office in Asia or a local partner?

For many brands, the next question is whether to open an office in Asia or work with an embedded local team.

Opening your own office can make sense if:

- You already have substantial volume concentrated in one hub.

- You can afford local leadership, HR, finance, and compliance overhead.

- You are ready to manage hiring, training, and retention in-market.

An alternative model is to embed dedicated local staff under a partner that already has legal entities and operational structures in place. In this model, brands often get:

- Dedicated project managers and coordinators on the ground.

- On-site follow‑up with factories in Vietnam, India, Indonesia, Bangladesh, or China.

- Local support on compliance, documentation, and problem‑solving without building a full office from scratch.

Key takeaway: Choose between your own office and an embedded local team based on volume, complexity, and your appetite for managing a foreign entity.

What does “boots on the ground” support in Asia really look like?

“Boots on the ground” is more than translating emails. In day‑to‑day operations, an effective local team in Asia will:

- Sit in factories during critical production stages, not just at shipment.

- Push for missing documents, corrections, and clarifications while production is still running.

- Catch small deviations early—before they turn into full batches of scrap or rework.

- Build long‑term relationships with factories, balancing firmness on standards with local cultural understanding.

This combination of real presence, process discipline, and relationships is what allows cost, quality, and compliance to move in the same direction rather than pulling against each other.

Key takeaway: Real control in Asia comes from people on the ground who represent your interests every day.

Turning Asia from a gamble into an advantage

Expanding manufacturing into Asia is no longer just about chasing cheaper labor. It is about building a supply chain you can explain, defend, and scale as enforcement and competition increase.

If you:

- Choose the right hubs for the right products.

- Map and verify your supply chain.

- Design quality and “reasonable care” into daily operations.

- Put trusted people on the ground in your key countries.