Negotiation, Contract Drafting & Signing

For $1800

Secure the Best Supplier Agreements with Local, Face-to-Face Negotiation.

In Asian manufacturing, strong negotiation and airtight contracts are the foundation of cost savings, quality assurance, and risk mitigation. At Asia Agent, we don’t just facilitate deals—we ensure you get the best terms, the right protections, and a solid contractual foundation.

Our Negotiation & Contract Drafting service, priced at $1,800, leverages deep local market knowledge and direct, face-to-face negotiations by our on-the-ground teams in Vietnam, India, China, Indonesia, and Bangladesh.

Why This Service Matters

- Face-to-Face Negotiations – Local teams meet directly with suppliers to build trust and secure better pricing, lead times, and payment terms.

- Full Contract Protection – We draft customized contracts that include intellectual property (IP) protection, supplier obligations, and legal safeguards.

- Payment Terms Optimization – We negotiate for longer payment terms, milestone-based payments, and minimized upfront deposits.

- Compliance & Risk Management – Ensure your contracts align with local laws and protect against supplier failures or disputes.

What’s Included in This Service?

1. Expert Supplier Negotiation

- Direct face-to-face negotiations by our local teams to secure the best deal.

- Transparent cost breakdowns to identify and eliminate supplier markups.

- Supplier relationship management to strengthen long-term partnerships.

2. Custom-Tailored Contract Drafting

- Bespoke supplier agreements tailored to your industry and business needs.

- Legal compliance checks to ensure enforceability in local jurisdictions.

- Inclusion of key protections: penalties for non-compliance, subcontracting restrictions, and dispute resolution mechanisms.

3. Intellectual Property & Confidentiality Protection

- NNN Agreements (Non-Disclosure, Non-Use, Non-Circumvention) to prevent suppliers from misusing your designs or selling your product.

- Legal registration of contracts in local jurisdictions to ensure enforcement if issues arise.

4. Payment Terms & Financial Risk Management

- Negotiation of payment schedules that protect your cash flow.

- Minimized deposit requirements to reduce financial risk.

- Penalty clauses for delays and quality issues.

5. Supplier Performance & Risk Assessment

- Background checks on supplier credibility and past contract adherence.

- Evaluation of contract risks before signing to prevent future disputes.

Deliverables

- Face-to-Face Negotiation Report – Detailed summary of negotiation outcomes.

- Custom Supplier Contract – Legally compliant and aligned with your business needs.

- IP & Confidentiality Protection – Secure NNN agreements and enforceable terms.

- Risk & Compliance Report – Ensuring supplier obligations and contractual protections are met.

Pricing

$1,800 per supplier agreement

For multi-supplier contracts or ongoing supplier negotiations, contact us for customized pricing.

How It Works

1️. Submit Your Request – Provide supplier details and key contract concerns.

2️. Asia Agent Conducts Negotiation – Our local team meets with the supplier for direct negotiations.

3️. Contract Drafting & Legal Review – We prepare and refine the agreement based on your priorities.

4️. Final Contract Signing – We oversee execution and ensure compliance.

Expert Negotiation & Contract Services: Your Questions Answered

Improve your manufacturing contracts with our service, leveraging expert negotiations and local expertise in Asia for strategic success.

Asia Agent doesn’t rely on emails or remote negotiations—we conduct face-to-face, on-the-ground negotiations with your suppliers through our local teams in Vietnam, India, China, Indonesia, and Bangladesh.

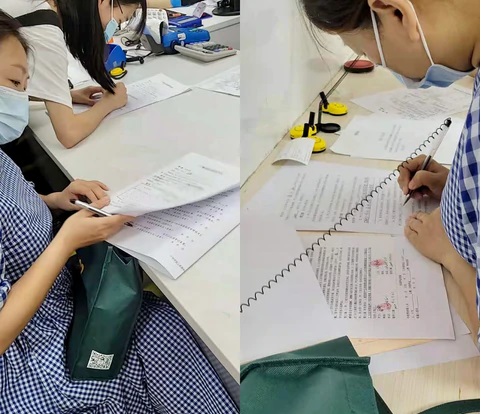

When dealing with suppliers, a physical presence changes everything. In many Asian cultures, business is built on trust and relationships, not just contracts. By meeting suppliers in person, we can:

- Strengthen your position by showing commitment and seriousness.

- Identify red flags in real-time that would be impossible to spot remotely.

- Gain insider insights on supplier operations, financial health, and priorities.

While many sourcing agents only negotiate through emails, our local teams go directly to the factory, speak with decision-makers, and get you better terms than remote buyers typically receive.

Unlike Western business cultures, where negotiations can be straightforward and contract-driven, many Asian suppliers rely heavily on personal relationships, hierarchy, and long-term trust.

By negotiating in person, our local teams can:

- Read between the lines – Many suppliers will agree to terms via email but change conditions later. Face-to-face meetings allow us to assess their real commitment.

- Pressure suppliers with competition – Being on-site allows us to reference other local factories and their offers, giving us leverage to negotiate better pricing and terms.

- Gauge financial stability – Some suppliers struggle with cash flow, which can delay orders or lead to quality compromises. By visiting the factory, we assess whether the supplier is in a position to meet your order commitments.

Without direct negotiations, buyers risk dealing with middlemen, inflated prices, or unreliable suppliers.

We physically meet with suppliers to discuss cash flow realities, risk factors, and long-term order commitments, allowing us to:

- Negotiate longer payment terms – Suppliers typically demand 30% to 50% deposits before production, but we often reduce upfront costs by leveraging on-the-ground credibility and showing that we are actively involved in supplier management.

- Push for milestone-based payments – Instead of paying large deposits upfront, we structure payments based on production milestones, ensuring you only pay for what is delivered and reducing financial risk.

- Eliminate unnecessary markups – Some suppliers inflate prices based on assumed risk or perceived buyer inexperience. By meeting in person, we remove uncertainty, leading to better pricing and terms.

Additionally, when we visit a factory, the supplier understands that if the client can send someone to inspect his facility, he can just as easily send us to another factory. This puts pressure on the supplier, as they realize that they are competing for the order. They know they can either agree to fair terms—or risk losing the business to another supplier that we can visit next.

This face-to-face approach shifts negotiation power to the client, ensuring better deals, lower risks, and stronger payment terms.

Asia Agent ensures that all contracts are legally enforceable in the supplier’s country, rather than relying on agreements drafted under foreign legal systems that may not hold up in local courts.

We navigate local regulations and contract specifics through:

Local Legal Expertise & Jurisdictional Advantage

Our contracts are drafted with local legal experts who specialize in business law, contract enforcement, and supplier disputes in Vietnam, China, India, Indonesia, and Bangladesh.

We register agreements under the supplier’s local legal system, ensuring real enforceability instead of relying on international arbitration, which can be costly and difficult to execute.

If legal action is needed, we have on-the-ground teams to escalate disputes through the appropriate local authorities.

Culturally-Aligned Contract Negotiation

Contract terms are structured to align with regional business customs, ensuring that suppliers fully understand the terms before signing—eliminating future excuses like “I didn’t know what I agreed to.”

We negotiate in person, allowing us to identify hidden supplier concerns that may lead to contract disputes later on.

Incorporating Supplier-Specific Legal Protections

NNN Agreements (Non-Disclosure, Non-Use, Non-Circumvention): Protects your intellectual property (IP) and designs, preventing suppliers from selling your products to local markets.

Payment & Performance Security Clauses: Prevents suppliers from taking deposits without delivering on production deadlines.

Quality Assurance & Penalty Clauses: Ensures strict quality control requirements, with financial penalties if defects exceed agreed limits.

Anti-Subcontracting Agreements: Blocks suppliers from outsourcing production to lower-quality factories without your consent.

Supplier Compliance with Local & International Trade Laws

We verify that suppliers comply with local trade laws, labor laws, and environmental standards, preventing risks related to forced labor, unauthorized subcontracting, or non-compliance with export regulations.

If a supplier’s certifications or compliance documents are found to be fake, we escalate the issue immediately.

Yes. Every contract we draft is fully customized to match your industry’s specific risks, regulations, and supplier expectations. We don’t use generic templates—we tailor every agreement to protect your intellectual property, pricing, quality standards, and supplier obligations.

How We Customize Contracts for Different Industries

1. Intellectual Property (IP) Protection – Crucial for Proprietary & Branded Products

For industries where designs, formulas, or product innovations are at risk of being copied, we incorporate:

- NNN Agreements (Non-Disclosure, Non-Use, Non-Circumvention) to prevent factories from selling your product to local markets.

- Exclusive Manufacturing Rights that stop suppliers from working with competitors using your designs.

- Legal Penalties for IP Violations, enforceable in China, Vietnam, India, Indonesia, and Bangladesh.

✅ Best for: Electronics, fashion, cosmetics, furniture, automotive, industrial equipment.

2. Quality Control & Inspection Clauses – Critical for Regulated Industries

For industries where compliance failures can result in recalls or legal action, we include:

- AQL Standards (Acceptable Quality Level) in contracts, ensuring defect limits are strictly enforced.

- Mandatory Third-Party Inspections Before Shipment to avoid receiving defective or substandard products.

- Rework & Replacement Liability, forcing suppliers to fix or replace faulty goods at their expense.

✅ Best for: Consumer electronics, medical devices, beauty & skincare, industrial manufacturing, food & supplements.

3. Pricing & Payment Term Customization – Key for Bulk & Seasonal Orders

For industries that deal with fluctuating costs or high-volume orders, we negotiate:

- Fixed Pricing Contracts for Stability, ensuring suppliers don’t raise prices mid-order.

- Milestone-Based Payment Structures instead of high upfront deposits, reducing financial risk.

- Penalty Clauses for Production Delays, preventing factories from pushing your order back in favor of larger clients.

✅ Best for: E-commerce, private label brands, seasonal fashion, furniture, home goods.

4. Compliance & Regulatory Safeguards – Essential for Export Markets

For industries where government regulations require strict testing and certification, we secure:

- Supplier Liability for Non-Compliance, making factories responsible for meeting all regulatory requirements.

- Mandatory Certification Verification, ensuring ISO, BSCI, GMP, FSC, and REACH compliance before production begins.

- Legal Guarantees for Safety & Compliance, protecting against chemical bans (PFAS, RoHS, Prop 65, REACH, etc.).

✅ Best for: Children’s products, electronics, textiles & fashion, beauty & skincare, food packaging.

Yes. Unlike many sourcing agents who only send contracts electronically, Asia Agent physically visits suppliers during contract finalization to ensure they fully understand and commit to the agreement before signing.

A supplier signing a contract remotely is not enough—in many cases, they may later claim they didn’t understand certain clauses or try to change terms after the fact. This is why our local teams conduct face-to-face contract finalization meetings to ensure the supplier is 100% aligned with your expectations.

How Our Supplier Visit Strengthens Contract Enforcement

1. In-Person Review with Factory Management

- Our team meets directly with factory owners and key decision-makers—not just sales reps—to discuss the contract in detail.

- We clarify pricing, payment terms, quality expectations, and penalties before the supplier signs.

- This prevents future misunderstandings where a supplier might later claim they were unaware of certain conditions.

✅ Why It Matters: Many suppliers skim through contracts when sent by email. Face-to-face discussions ensure they take it seriously.

2. Factory Walkthrough to Confirm Production Readiness

- Before finalizing an agreement, we physically inspect the factory to ensure:

- They have the machinery, workforce, and raw materials to meet your order.

- They are not outsourcing production to an unknown subcontractor.

- They understand and can meet your quality control requirements.

- If red flags are found, we negotiate contract adjustments before signing to eliminate risks.

✅ Why It Matters: Some suppliers sign contracts but fail to meet capacity or compliance standards—this step prevents surprises later.

3. Supplier Commitment & Psychological Pressure

- When a supplier meets us in person, they understand that your business is serious, well-represented, and closely monitoring the process.

- They know that if they don’t comply, we can easily visit competing factories and shift production elsewhere.

- This dynamic reduces the chances of price hikes, hidden fees, or order delays.

✅ Why It Matters: A supplier that sees a strong buyer presence is less likely to manipulate contract terms later.

4. Supervised Contract Signing & Document Verification

- We ensure that the correct factory representative signs the contract (e.g., owner, general manager) rather than just a sales agent.

- We verify that the business license, supplier identity, and legal details match the contract.

- We check that no changes are made after signing—a common trick some suppliers use to remove unfavorable clauses.

✅ Why It Matters: Some factories try to alter agreements after signing—our presence eliminates this risk.

Yes, our expertise spans across Asia's key manufacturing hubs, including China, Vietnam, India, Bangladesh, and Indonesia. Our local presence and understanding of each market’s unique landscape empower us to effectively negotiate and secure favorable terms across the region.

We include strict penalty clauses and clear breach-of-contract consequences to prevent suppliers from backing out or changing terms unfairly. If disputes arise, our local team can step in directly to resolve issues on your behalf.

Intellectual property (IP) theft is one of the biggest risks when manufacturing in Asia. Many factories reverse-engineer products, sell excess inventory on local markets, or register patents in their own name—leaving businesses exposed to unauthorized competition.

Asia Agent takes a multi-layered approach to IP protection, ensuring that your designs, formulas, molds, and confidential business information remain secure throughout the manufacturing process.

1. Legally Binding NNN Agreements (Not Just NDAs)

A Non-Disclosure, Non-Use, Non-Circumvention (NNN) Agreement is far stronger than a standard NDA (Non-Disclosure Agreement) and is specifically designed to prevent supplier-side IP theft.

Our NNN contracts include:

✔ Non-Disclosure – The supplier cannot share your product designs, formulas, or specifications.

✔ Non-Use – The supplier cannot use your IP to manufacture products for anyone else.

✔ Non-Circumvention – The supplier cannot bypass you to sell directly to your customers or competitors.

🔹 Why This Matters:

Many buyers mistakenly sign NDAs written under foreign laws, which are not enforceable in the supplier’s country. We draft NNNs in the supplier’s jurisdiction, ensuring that violators face real legal consequences.

2. Contractual Ownership of Tooling, Molds & Prototypes

One of the most common IP theft tactics is when a supplier claims ownership of molds, tooling, or samples and refuses to release them when you switch factories.

Our contracts:

✔ Clearly state that all molds, tooling, and custom parts belong to the client—not the factory.

✔ Include supplier obligations to return or destroy molds upon contract termination.

✔ Prevent factories from using your tools to produce unauthorized units.

🔹 Why This Matters:

Without legal protection, a factory can claim ownership of your molds and continue producing your product under a different brand.

3. Factory Selection & IP Risk Assessment

Not all factories are trustworthy when it comes to IP security. Before working with a supplier, we conduct a detailed background check, including:

✔ Company ownership records – Verifying who actually owns the business and checking for links to known counterfeiters.

✔ Past IP violations – Reviewing court cases, supplier blacklists, and previous disputes.

✔ Production capacity assessment – Ensuring that the supplier is not secretly producing extra stock for resale.

🔹 Why This Matters:

Many high-risk suppliers are repeat offenders when it comes to IP theft. Identifying red flags early prevents serious legal battles later.

4. Restricted Access to Sensitive Product Information

Asia Agent ensures that only essential personnel within the factory have access to your confidential product details, including:

✔ Splitting sensitive components across multiple suppliers – Preventing any one supplier from having full knowledge of the product design.

✔ Limiting access to core specifications – Only sharing detailed schematics with trusted partners.

✔ Preventing excess production – Monitoring material orders and preventing unauthorized extra units from being made.

🔹 Why This Matters:

Factories often produce extra units without the buyer’s knowledge, then sell them locally or to competing brands. By strictly monitoring production quantities, we prevent this from happening.

5. Local Legal Enforcement & IP Dispute Resolution

If a supplier violates your IP rights, Asia Agent takes swift legal action through local courts and enforcement agencies.

✔ Legal enforcement in China, Vietnam, India, Indonesia, and Bangladesh.

✔ IP theft escalation through government authorities – Many countries have strict anti-counterfeiting laws, and we ensure local authorities act against violators.

✔ Immediate factory intervention – If a supplier attempts to sell or misuse your IP, our team visits the factory to stop unauthorized production before it escalates.

🔹 Why This Matters:

Most buyers assume that legal action must be taken from their home country—but this is ineffective. We enforce contracts in the supplier’s own jurisdiction, where action can be taken quickly.

6. Trademark & Patent Registration Strategy for Asia

In many cases, protecting IP requires more than just contracts—it also involves securing trademarks and patents in key manufacturing regions.

✔ Trademark registration in China & Vietnam – Prevents factories from registering your brand name before you do.

✔ Defensive patent filings – Stops suppliers from patenting your own product in their name.

✔ Customs IP protection filings – Ensures that unauthorized shipments are flagged and seized before export.

🔹 Why This Matters:

Many brands lose control of their trademarks in Asia because a supplier registers them first. We ensure you own your brand name and product rights where it matters.

7. Ongoing Monitoring for IP Violations

IP protection doesn’t stop after production begins—we continuously monitor:

✔ Supplier behavior – Ensuring they aren’t secretly producing extra stock.

✔ E-commerce marketplaces – Checking for counterfeit versions of your product appearing on Amazon, Alibaba, and local platforms.

✔ Secondary market leaks – Preventing excess production from being sold to unauthorized buyers.

🔹 Why This Matters:

Factories often wait months before releasing unauthorized copies, assuming buyers won’t notice. We stay ahead of IP risks by proactively monitoring supplier activity.

Yes. Our local negotiators leverage supplier visits, competitor benchmarking, and cost analysis to negotiate better pricing. By discussing costs directly with factory owners, we identify where suppliers add unnecessary markups and push for fairer rates.

- Pricing & Payment Terms – Lower prices, extended payment schedules, and deposit reductions.

- Lead Times & Delivery Guarantees – Ensuring realistic timelines with penalties for late shipments.

- Quality Control & Inspection Rights – Allowing third-party QC checks before shipment approval.

- Intellectual Property (IP) Protection – Preventing factories from reselling your product or using your designs.

Many factories secretly subcontract orders to lower-quality manufacturers. Our face-to-face factory visits confirm who is actually making your product, and we add strict subcontracting restrictions in contracts to prevent unauthorized outsourcing.

If a supplier resists signing an agreement, it’s often a red flag. Our local team speaks directly with factory managers to resolve concerns, ensuring you don’t work with a supplier who plans to cut corners or break commitments.

Simply contact us to schedule a consultation. We’ll assess your supplier situation, production needs, and key negotiation goals, then deploy our local team for direct negotiations and contract finalization.